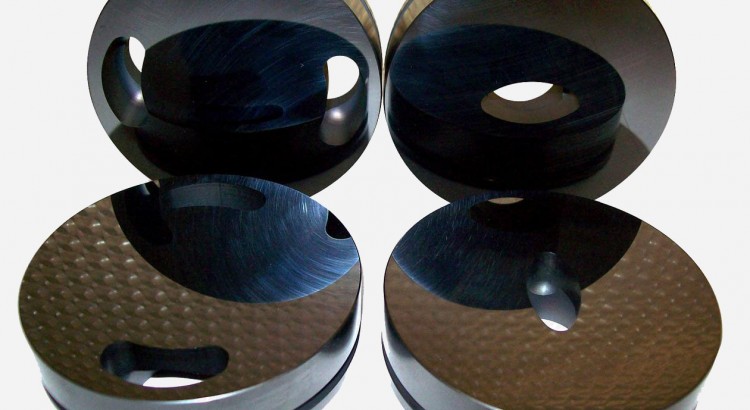

As an electronics brand, Yowu’s biggest strength has always been fitting audio technology into sleek, playful, aesthetically-pleasing designs aimed at Gen Z consumers. Yowu’s mastery of design is elegantly displayed in its Elf Wireless Earphone (also known as the Sphynx Earphone Series) products.

Compared to Yowu’s signature cat ear headphones, the Elf Wireless Earphones’ design is more graceful and exquisite. Next to the cute aesthetic of cat ears, elf ears have a more mature and ethereal appearance, giving this product a different appeal from most of Yowu’s products. For these reasons, this product will likely be more marketable to fantasy fans who are older than Yowu’s core demographic. Personally, I love these earphones’ design, fit, and light color customization features.

When it comes to visual appearance, Yowu products have always been a 10/10, but do its technical features hold up to scrutiny? The “elven nest” charging cast is sleek, streamlined, and easy to open. It also provides a hefty amount of battery life. However, my favorite features are the earphones’ dual noise reduction and cutting-edge Bluetooth 5.0 connectivity. The dual noise reduction really boosts the earphones’ sound quality during gaming sessions, wireless phone calls, and music listening parties. The Bluetooth features and LDS antenna also boost these wireless products’ efficiency and stability. If you’re feeling adventurous enough for some real-life questing, the earphones are also water-resistant, so you can live out your woodland elf fantasies by taking them outdoors.

Overall, these earphones are a worthy addition to anyone’s collection. If you want to add a little fantasy to your life, they look fantastic and work great.