Medical device coatings have come a long way in terms of development and application. Years of extensive research have led to a product capable of entering the human body without harming the patient or exposing them to the risks of infection. These coatings vary in form and can be as simple as thin metal or as advanced as pore-laden polymer coating.

Creating the Coating

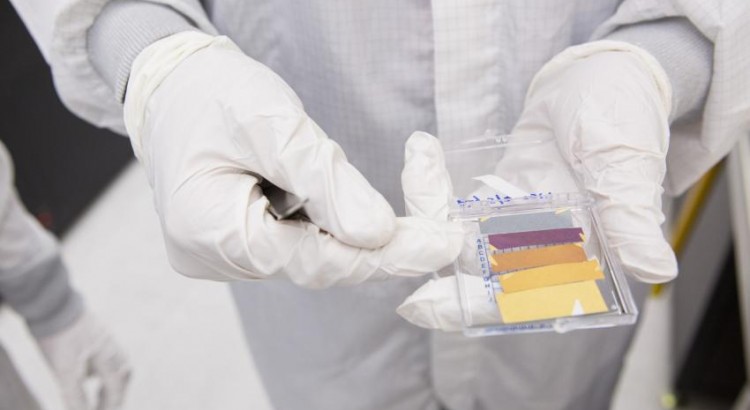

There are multiple forms of technologies that engineers can use to create the coating. Being such a vital part of the process, the application of the coating must be taken care of with precision and care. A thorough and complete inspection is necessary to check for any potential detrimental effects. Upon approval by inspectors, the coating is then introduced to the market.

The creation of the coating can be done in various intricate ways such as: PVD thermal evaporation, surface polymerization, spray coating etc. Through all of these methods, viscosity plays a huge role in the delivery of the liquid to the surface, therefore determining its efficiency.

The Importance of Coating

The human body’s defense mechanism is extremely complex. The insertion of medical devices will naturally provoke the body to defend itself. Certain plastics, or metals, are compatible with the body but lack the properties which would make them effective. The same goes the other way around where some materials irritate the body but once inserted, would generate a relatively positive response. This is where coating application blossoms.

Minimal irritation and inflammation following placement of the medical device is important for the patient’s well-being. A coated medical device can not only achieve that, but can also: encourage tissue growth and promote a rapid healing process, severely decrease the chance of infection due to device placement, and even manipulate the body’s defense system into “accepting” it. Through rapid-fire advancements, coating applications have become an integral part of medicine.

Flow Control

To improve production processes, new flow control technologies have been produced. This is especially important in the area of liquid spray coating. By utilizing this type of technology, one will see an increase in uniformity which coating is dependent upon.

Wrapping it Up

With today’s advanced coating discoveries, medical science can now apply advanced methods such as thin film evaporation and chemical vapor deposition to technologies giving them the potential to reach new heights.

———————————————————————————————

Denton Vacuum transforms barriers into thin-film technology breakthroughs for customers across the globe in providing vacuum deposition systems.