A new form of coating technology, diamond like carbon has risen to the ranks to become one of the most highly resistant and resilient type of coating available on the market today.

Diamond like Carbon Properties

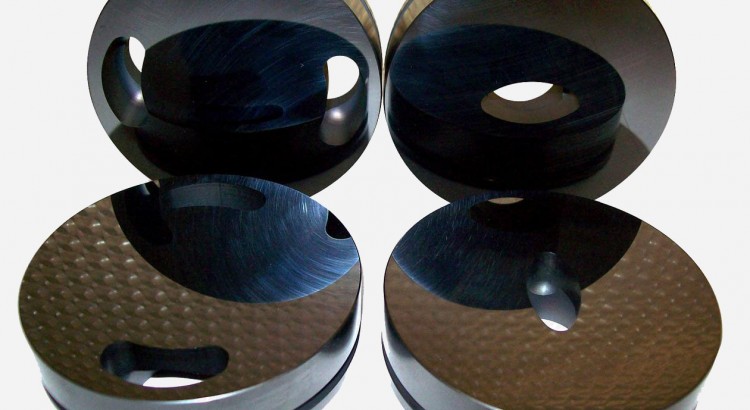

The excellent properties of diamond like carbon are what make them stand out from other methods of coating. Boasting an incredibly high wear resistance as well as an extremely low friction coefficient, diamond like carbon applications have been incorporated in a variety of industries such as automotive and oil and gas.

DLC coatings have been known to perform tremendously well under extreme environments that expose the material to high amounts of pressure, abrasive conditions, and volatile interaction. This makes the application of DLC ideal for pipe joints or interior tubing.

DLC coatings have also found a home in the world of medicine. The rising implementation of medical device coatings in invasive procedures has created new leverage on improving a patient’s recovery and sustainability. An example of a medical device coating would be a catheter being inserted into the patient. By applying a coating over the catheter, it will drastically decrease the chance for an infection or even a blood clot from occurring and maximize the safety of the patient.

Methods of Deposition

DLC can be deposited by a variety of methods – chemical vapor deposition, electroplating, flame spray, physical vapor deposition, etc. It should be duly noted that each method has its pros and cons, but these challenges are constantly being met by researchers that are developing new techniques to minimize any risks and issues.

Practical Coating Usage

Coloring steel watches has been a growing industry for some time now. Now, steel is incredibly difficult to recolor. Not only will natural methods come off with wear, but the quality will just lack in the end.

For optimal coating, there are two processes that are utilized: physical vapor deposition and diamond like carbon. Both processes do the job but DLC utilizes the properties of carbon to create a smooth and extremely tough end result. It’s been known that PVD wears off after years of usage – these are just based on opinions.

As mentioned before, DLC coating’s properties make them useful for watches – the abuse that they take unknowingly throughout the day is far more rugged than you might realize. Abrasion and water resistance are two of the more common properties that watches need to survive on a day-to-day basis. DLC coatings are essentially a versatile protective shell that is built to last.

———————————————————————————————

Denton Vacuum, LLC manufactures sputtering systems primarily designed for vacuum deposition techniques.